BOLTING AND POSITIONING SYSTEMS

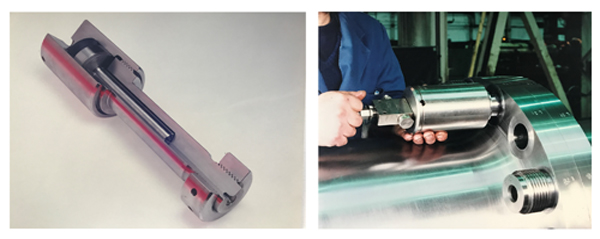

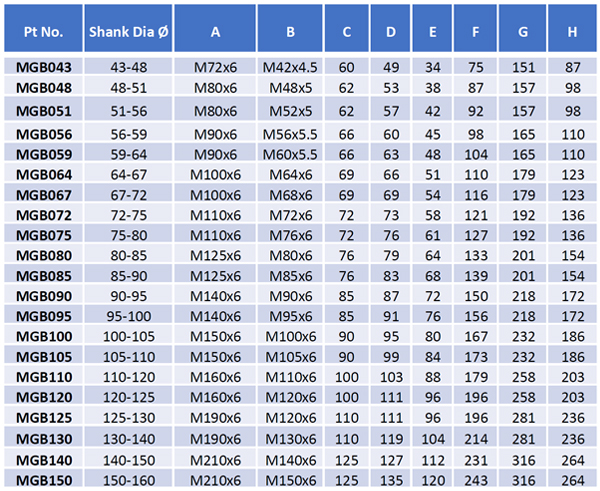

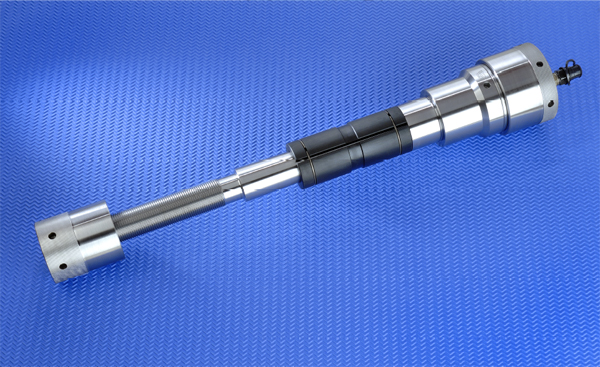

Pilgrim's MORGRIP hydraulically installed bolt

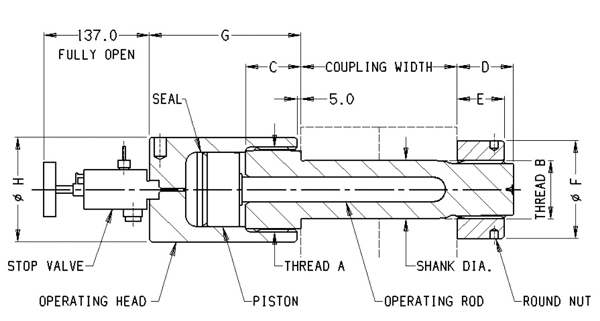

The MORGRIP Bolt is a hydraulically actuated bolt. designed to provide a cost effective truly fitted bolt assembly. The Bolt eliminates the need for hammering conventional bolts into holes. which often causes scoring of both bolt and hole surfaces.

The MORGRIP bolt can be repeatedly installed and removed quickly and without damage to either the Bolt or the hole. The principle on which the MORGRIP Bolt works is based upon Poissons Ratio whereby when a round bar of steel is stretched within its elastic limit, its diameter will reduce. The stretching force is applied to the Bolt by a hardened stell rod located down the center hole in the Bolt. Operating Gear is screwed onto the head of the Bolt, and when pressurised it exerts a force through the rod to stretch the Bolt. The Operating Gear is pressurised using one of Pilgrim's MORPRESS pump packs.

Once pressurised, the Bolt can be installed in the hole. A nut is attached (if a through hole application) and nipped tight. The pressure is then released to bring about a reduction in the length and corresponding increase in the diameter of the Bolt. The Bolt can be installed remotely from the Pump by using a stop valve fitted to the Operating Gear to lock in the hydraulic pressure. The Bolt is now ready to service. For removal, the above procedure is reversed.

Typical Applications

- Ship Drive Shaft Couplings

- Steam Turbine Couplings

- Pitch Blade Propellers

Benefits

- Saves time

- Reduces cost

- Accurate and reliable

- Quick and efficient to install and remove

- Custom Design

- Safe

Pilgrim's Coupling Hole Alignment Tool (CHAT)

The Coupling Hole Alignment Tool (CHAT) is a further development from the Pilgrim product portfolio. Designed in response to OEM maintenance and end user requirements. It achieves coupling hole alignment quickly and to a tolerance that permits effective bolt installation or removal.

The CHAT hydraulically expanding tool is based upon the same principle as the Radial Fit Bolt saving time and therefore reduces cost during the alignment and closure of shaft couplings. Depending upon coupling size, each CHAT package consists of between 3 and 4 tool assemblies. The tools are inserted into equispaced flange holes and are simultaneously pressurised to align the coupling holes. The coupling faces are then closed using the tools in preparation for installation of the coupling bolts.

Designed and manufactured specifically to each coupling

Typical Applications

- Steam Turbine Couplings LP to IP, IP to HP & HP to Gen

- Gas Turbine Couplings LP to IP, IP to HP & HP to Gen

Benefits

- Saves time

- Reduces cost

- Aligns and closes couplings

- Accurate and reliable

- Quick and efficient

- Versatile

- Powerful and safe

- Easy to handle and operate

- Suitable for spigotted or plain Coupling

The world’s most advanced propulsion shaft coupling solutions

- An innovative alternative to traditional shrink-fit bolts

- Faster to install and remove

- Safer and easier to handle - no bolt freezing

- Significantly lower life cycle costs

- Last the complete life of the vessel

- No re-machining

- Newbuild or direct retrofit

- Reliability means more effective planning

- OEM approval

VLCC with ABS Classification installed with Pilgrim Radial Fit Bolts at the engine to 1st intermediate coupling flange

The product of more than sixty years of development and innovation, Pilgrim Radial Fit Bolts utilise hydraulically-induced mechanical expansion to deliver significant benefits over conventional shrink-fit bolts.

Used extensively throughout the world by the marine, power and oil industries, our coupling bolt systems are backed by the most stringent quality control procedures and the highest standards of service.

Whatever the application, we have the skills and resources to design, manufacture and supply solutions that are at the very forefront of coupling technology.

- Radial Fit Bolts

- Morgrip bolt

- Other bolting solutions

- Hydraulic nuts

- Marine ringjacks

- Oil injection systems

- Hydraulic pumps (hand and air driven)

- Full range of support services

The problems associated with traditional shrink fit bolts

- Varied and inaccurate interference levels

- Varied and inaccurate clamping forces

- Bolt holes often damaged on removal

- Bolts often destroyed during removal

- Can be hazardous to handle

- Difficult to plan the engineering time and resources

- High potential for operating delays

- Recurring problems – whenever shrink fit bolts are removed and re-installed

Traditional shrink fit bolts are manufactured with an outer diameter that is larger than the coupling hole. This means they first have to be frozen in liquid NO2 or dry ice and alcohol until the outer diameter reduces sufficiently to allow the bolt to be inserted in the hole.

As the shrink fit bolt returns to its normal temperature it expands back to its normal size. The result: an interference fit is formed.

Installation of shrink fit bolts can be difficult and at times hazardous. With a typical clearance condition of 0.01mm to 0 0.04mm, internal alignment of the bolt has to be perfect otherwise the bolt can become stuck or only partially inserted into the hole - a frequent occurrence.

Removal of shrink fit bolts during a tailshaft survey, bearing inspection or general shaft maintenance programm can be equally problematic, with many bolts breaking. When this happens, the bolts have to be drilled out and the holes re-bored, honed and made ready to receive new bolts.

As a ‘critical pathline’ component, operational delays often occur as a result of shrink fit bolt problems. New bolts have to be sourced and modified drawings have to be approved by Class – resulting in a costly process that can lose hundreds of thousands of dollars per year across a fleet.

This can be avoided by using Pilgrim’s advanced coupling bolt technology.

The Innovative, technically proven solutions developed by Pilgrim

Installed at the face-to-face coupling flanges used to connect the different sections of the propulsion shaft, Pilgrim Radial Fit Bolts are fitted and removed in just ten – fifteen minutes. The complete installation and removal processes are extremely reliable and predictable, allowing resources and engineering

time to be accurately forecast.

Unlike traditional bolts, Pilgrim Radial Fit Bolts are not over-sized – they fit in the hole, no shrinkage is necessary. As will be appreciated, this is a huge advantage.

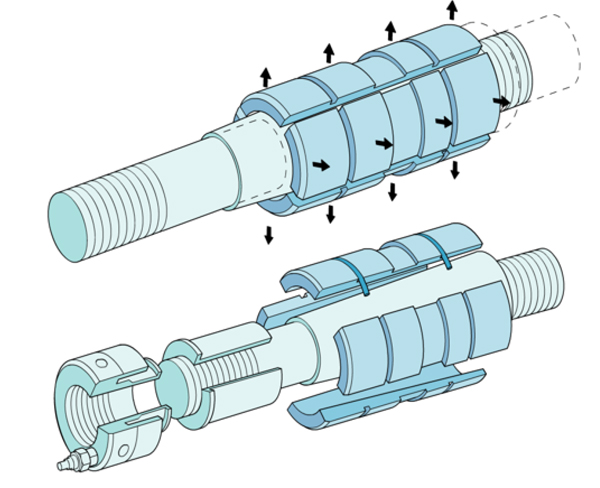

The Radial Fit Bolts themselves consist of a tapered bolt and an internally tapered sleeve. When the bolt is hydraulically pulled into the sleeve, the outer diameter of the sleeve is forced to expand inside the hole and form a pre-engineered interference/pressure fit. The bolt is then hydraulically tensioned to provide a pre-determined secure clamping force, pulling the two flanges together.

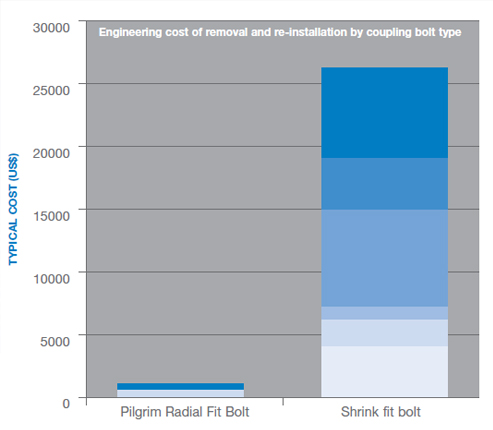

Engineering life cycle cost comparison

Engineering life cycle costs comparing the use of Pilgrim Radial Fit Bolts with traditional shrink fit bolts.

Case example:

Installation to an Aframax tanker, at both the ‘Eng to Int’ and ‘Int to Prop’ flanges, with 12 bolts fitted to each coupling flange.

Class required ‘Tailshaft Surveys’ every five years.

Over a twenty-year period the estimated saving to the ship owner/manager is in the region of US$70,000. This excludes the loss of operating time and subsequent loss of revenue.

| Pilgrim Radial Fit Bolt | Shrink fit bolt | |

|---|---|---|

| Bolt removal time for 24 bolts at US$200/hr | 400 | 7200 |

| Hole re-bore at US$200/hole | 0 | 4000 |

| New Bolts | 0 | 8000 |

| Class Costs | 0 | 1000 |

| Freezing at US$ 100/bolt | 0 | 2000 |

| Installation time for 24 bolts at US$200/hr | 600 | 4000 |

Advantages to ship yards

- Faster installation

- Less hazardous – no freezing, easier handling

- Easy removal and re-installation to correct shaft line mis-alignment

- Accurate, secure pre-engineered interference fit and clamping loads across flanges

Advantages to ship owners

- Faster tailshaft surveys

- Fully re-usable for entire life of vessel

- Virtually eliminates the need for secondary engineering to the shaftline

Advantages to ship managers

- Operating time maximised

- Virtually no need for secondary engineering

- Reduced maintenance budget

- Eliminates the difficulties associated with bolt removal

- Makes planning of central docking schedules easier

- Accurate, secure, pre-engineered interference fit and clamping loads across flanges

Cookies Policy

Lorem ipsum, dolor sit amet consectetur adipisicing elit. Sed eveniet expedita cum autem, provident perferendis earum libero hic quasi excepturi modi voluptas eligendi ducimus quae nulla quis sapiente voluptate odio!

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Aut excepturi tenetur sunt quo, sequi reprehenderit assumenda facere unde, deserunt odio consequuntur non totam vel suscipit. Eum officia reprehenderit sit, inventore adipisci consequuntur commodi ducimus quisquam vel culpa dolorem error modi, aut distinctio odio excepturi non ut reiciendis obcaecati quis repellendus quia fuga. Corporis, sunt maiores eum recusandae distinctio exercitationem iure repellat autem saepe non sed reiciendis repellendus dolore doloremque ducimus ab alias modi itaque praesentium rerum ratione molestiae porro ullam. Quasi nostrum quas quia tempora recusandae, iusto voluptate commodi consequatur consequuntur! Id minus sequi nam enim omnis vitae aliquam ipsum ratione, neque sint vero ab repellendus quis nihil doloremque dolorem et reprehenderit, rem, repellat reiciendis earum ut doloribus totam? Corrupti omnis, sapiente, veniam eaque unde possimus quia in sit nihil qui totam asperiores amet suscipit soluta maiores. Reprehenderit repellendus corporis nihil amet, voluptate atque minima soluta, hic ea libero neque quod! Non suscipit iste odio error eius recusandae voluptates reiciendis dolorum qui libero nostrum eveniet, quod magnam amet laboriosam quaerat numquam minus explicabo delectus consequuntur at voluptatum quibusdam aspernatur doloremque! Aliquam, atque, recusandae veritatis, ab enim temporibus earum qui sunt cumque ipsa ducimus eum explicabo exercitationem non quidem velit vel.

Section 01

Lorem, ipsum dolor sit amet consectetur adipisicing elit. Consequuntur eos quasi facilis animi maiores ut cum repellendus, placeat ipsam voluptate quos quas nobis optio ipsum at soluta doloribus sapiente ullam nemo? Dolore nisi labore, quas reprehenderit aspernatur quo nobis doloremque, numquam quis ipsa quidem dignissimos beatae necessitatibus nulla dolor obcaecati, minus explicabo? Aliquid laboriosam rerum omnis molestiae eveniet odit officia distinctio adipisci ad dolorem explicabo, optio ducimus! Dolore, excepturi laudantium? Aut sed vero expedita optio qui nihil consequatur, adipisci, minus rem repudiandae earum, eius quis deserunt maiores! Reiciendis vel maiores modi id debitis harum fugit, odit tempora tenetur maxime mollitia.

Lorem ipsum dolor sit amet consectetur adipisicing elit. Suscipit mollitia recusandae sunt a quod explicabo et cum, perspiciatis iste, excepturi voluptatibus. Quo ex iure veritatis exercitationem saepe consequatur repudiandae minima!

Section 02

Lorem ipsum dolor sit amet consectetur adipisicing elit. Harum, labore praesentium veritatis incidunt in doloribus id minima rem laudantium optio dolor debitis accusamus veniam dicta quidem ipsum porro mollitia necessitatibus aliquid corrupti saepe dignissimos blanditiis deleniti! Quia, esse culpa. Totam repellat veniam pariatur repudiandae saepe quae officia corrupti quis quo nesciunt iusto at incidunt vero, praesentium neque illo vel id voluptas deserunt dicta dignissimos quod! Odit, eligendi error? Commodi repellendus optio aliquid, quidem rerum eaque, atque soluta possimus, doloribus amet nemo. Soluta molestias possimus itaque atque aut porro est ipsa nobis aliquam repellendus corporis totam quo mollitia quasi at, tempora animi, reiciendis dolore dolorum. Voluptate perferendis cumque vero voluptatibus eaque? Voluptas consequatur alias minima obcaecati amet voluptates provident rerum ducimus doloribus voluptatem, quis mollitia unde tempore perferendis nostrum, debitis magni deserunt explicabo odio veritatis tenetur. Est recusandae debitis expedita nam amet itaque facilis ut reiciendis fugit molestiae quis porro aperiam veniam, deleniti explicabo quod vitae, dolore officia sapiente numquam ratione, et voluptatibus. Quos cupiditate excepturi harum amet impedit doloribus dicta, fuga distinctio fugit exercitationem ipsam molestias maxime doloremque voluptatum nesciunt saepe eligendi? Dignissimos culpa aperiam eaque animi delectus quaerat repellendus perferendis officiis in reprehenderit asperiores eligendi hic aut, labore quas? Labore esse quae temporibus, obcaecati facilis blanditiis asperiores quod nisi rerum eaque velit tempora molestias sit modi voluptate. Eaque ab sed eligendi quas ex deserunt tempore molestias dolor quo culpa, at velit, iste, perspiciatis aperiam rerum recusandae nobis similique vitae! Provident necessitatibus deleniti repellendus neque maiores assumenda enim, incidunt earum ipsum quo corrupti placeat vitae libero alias architecto eveniet facere sint minus dolore id voluptates. Quis quasi voluptas id ipsum architecto provident ipsam eaque! Repudiandae, delectus? Accusamus aliquam, ullam vitae corrupti autem culpa distinctio eius aliquid tempore pariatur tempora officiis sed eos hic, dolor natus, nesciunt ducimus facere adipisci. Iure!