DESULFURIZATION SYSTEM FOR SHIPS (DE SOx)

International Maritime Organization (IMO) has set the maximum allowable content of sulfur in fuel used by ships through MARPOL 73/78 ‘International Convention for the Prevention of Pollution from Ships’ that entered into force in 2005. All ships operating in Sulfur Emission Control Areas (SECA) have been required to use fuel with a sulfur content of 1% or less since July 2010 and to use fuel with the sulfur content of 0.1% or less since 2015.

In addition, the regulatory requirement of using fuels with a sulfur content of 0.5% or less in all oceans throughout the world is to take effect in 2020. To meet the requirements on the permitted sulfur levels in ship fuel, ships must use fuel with low sulfur content or be equipped with a desulfurization system that meets IMO, MARPOL 73/78 regulations.

Low-sulfur fuel is a viable option on a short term basis but is too expensive to use which makes the fuel gas desulfurization system combined with a continued use of existing high sulfur fuels an optimal alternative in terms of long-term operating costs while meeting environmental regulations.

Emission Control Areas

Emission Control Area. Emission Control Areas (ECAs), or Sulfur Emission Control Areas (SECAs), are sea areas in which stricter controls were established to minimize airborne emissions from ships as defined by Annex VI of the 1997 MARPOL Protocol

| Area | Sulphur Limit | Scrubbers |

|---|---|---|

| Global | 0.50% (2020) | Local restrictions may apply for Open-loop scrubbers |

| SECA | 0.10% | Yes |

| EU | 0.10% in all ports | Open-loop scrubbers restricted In some countries |

| China | 0.50% in national Waters (12 nm) | Certain restrictions apply for Open-loop scrubbers |

| California | 0.10% within 24 nm | No, only with research exemption |

SOx emission control areas reported to IMO are the North Sea, the Baltics and the North American seas. In addition, IMO adopted Res. MEPC. 202 (62) and the U.S. Caribbean region has been additionally designated as NOx and SOx emission control areas. Moreover, as a measure to control smog within China, the Chinese government has designated Yangzi River (Shanghai), Pearl River (Hong Kong, Macao) and Bohai Bay as the emission control areas, and intend to expand regulation in stages.

Products

U-Type

The footprint in the U‒Type Scrubber is wider in width and shorter in height than that in I-Type. In the U‒Type Scrubber System, each exhaust gas discharge medium (ex. Main engine, aux. engine and boiler) has its own bypass line, and dry mode is not applicable. Packing is used in the inside of the Scrubber.

| Capacity | PaSox smart V2.0 | PaSox smart V3.0 | Reduction | |||

|---|---|---|---|---|---|---|

| MW | Footprint (m2) | Volume (m3) | Footprint (m2) | Volume (m3) | Footprint (m2) | Volume (m3) |

| 5 | 9.12 | 70.68 | 7.72 | 51.19 | 15.3 | 27.5 |

| 10 | 17.68 | 156.46 | 14.65 | 108.52 | 17.1 | 30.6 |

| 15 | 26.77 | 261.05 | 21.9 | 176.84 | 18.2 | 32.2 |

| 20 | 32.9 | 345.65 | 28.44 | 242.34 | 13.5 | 29.8 |

| 30 | 50.31 | 593.65 | 42.07 | 379.22 | 16.4 | 33 |

| 40 | 66.48 | 851.04 | 55.38 | 562.73 | 16.7 | 33.8 |

I-Type

The footprint in the I–Type Scrubber is narrower in width and higher in height than that in the U-Type. In the I–Type Scrubber System, Dry mode is available, and a bypass valve is not applied. Packing is not used in the inside of Scrubber. I-Type is recommended when there is not enough space for a bypass line in the funnel and the difference in the total gas exhaust flow of the combustion engine is not significant.

| Capacity | PaSox smart V2.0 | PaSox smart V3.0 | Reduction | |||||

|---|---|---|---|---|---|---|---|---|

| MW | Diameter (m) | Height (m) | Volume (m3) | Diameter (m) | Height (m) | Volume (m3) | Height (m) | Volume (m3) |

| 5 | 2.25 | 11.35 | 45.13 | 1.85 | 11.17 | 30.04 | 1.5 | 33.4 |

| 10 | 3.1 | 13.4 | 101.14 | 2.5 | 12.06 | 59.20 | 10 | 41.5 |

| 15 | 3.75 | 14.95 | 165.12 | 3.05 | 12.84 | 93.81 | 14.1 | 43.2 |

| 20 | 4.3 | 16.15 | 234.53 | 3.5 | 13.64 | 129.50 | 16.6 | 44.8 |

| 30 | 5.2 | 18.25 | 387.58 | 4.25 | 14.32 | 203.15 | 21.5 | 47.6 |

| 40 | 6 | 20.01 | 568.31 | 4.85 | 15.24 | 281.55 | 24.1 | 50.5 |

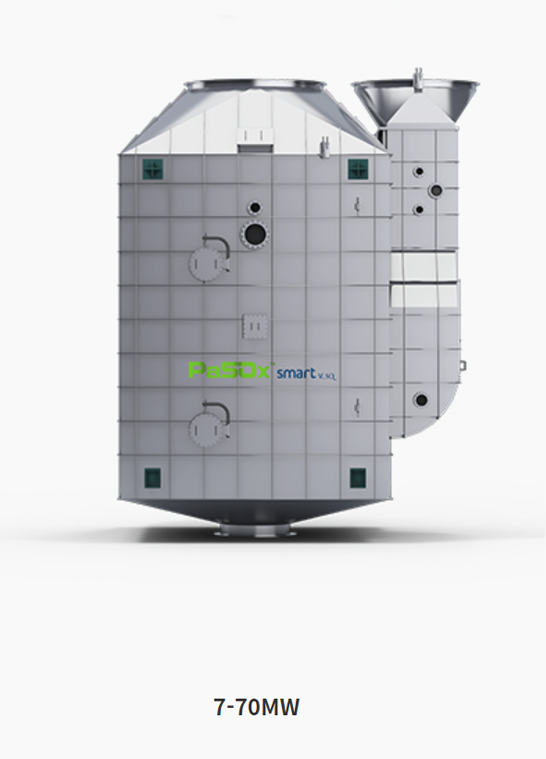

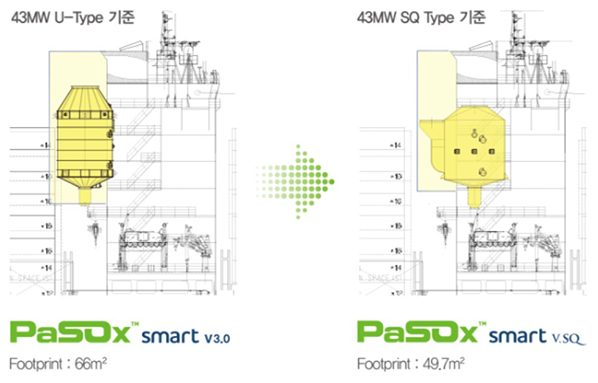

We provide solutions optimized for the characteristics of different ships, from small-sized to large-sized. We also offer square scrubbers that can keep cargo loss to a minimum for certain vessel types.

PANASIA’s Scrubber PaSOx™ V.MCR offers a range of solutions that fit installation spaces on board limited to small-sized desulfurization systems (1 to 6MW), which have been optimized for small- or medium-sized ships. It will be the ideal solution that can efficiently respond to the sulfur dioxide regulations.

Installation Application

General Type

- Conventional system in which a scrubber is installed inside the funnel.

- Keeping the installation space to a minimum.

- Can be installed on both new and existing ships.

- Inspections can be done during operation.

Flat Bottom Type

- Can be installed in a short span of time.

- Installation costs can be reduced.

- Can be installed on weather decks.

- Less limited installation space.

- Need to install a platform required for Inspection during operation.

Skid Type

- Combined package type installation including piping, GMS, WMS, and control panel.

- Reduced installation time.

- Reduced installation costs.

- Protect the system from external environmental factors.

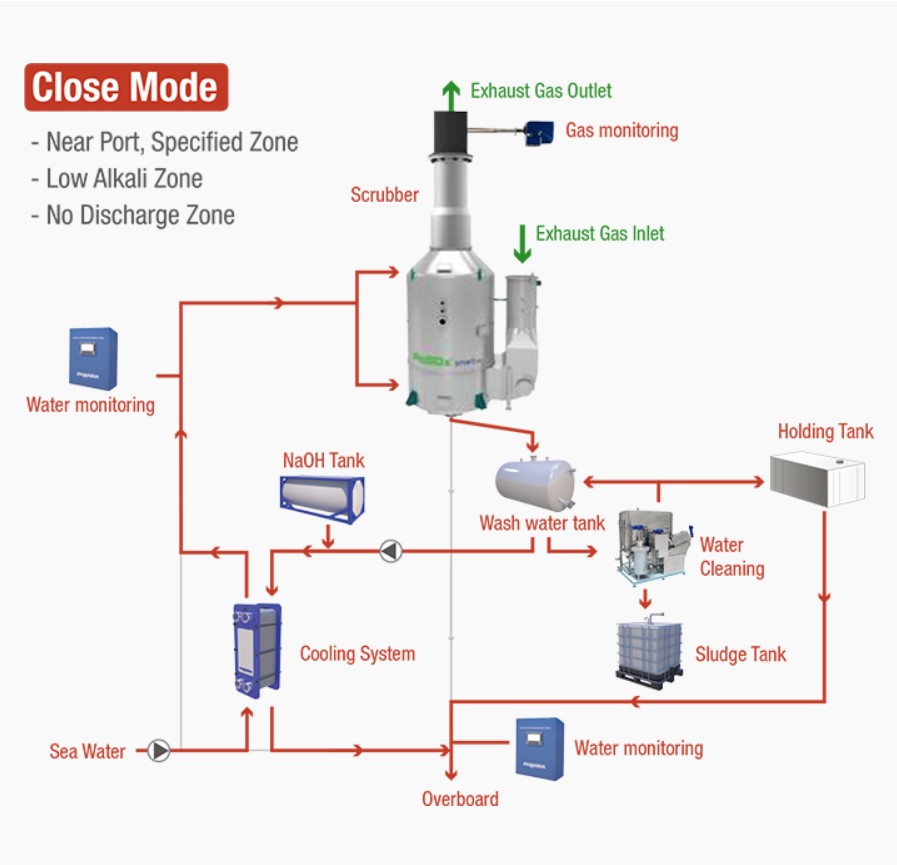

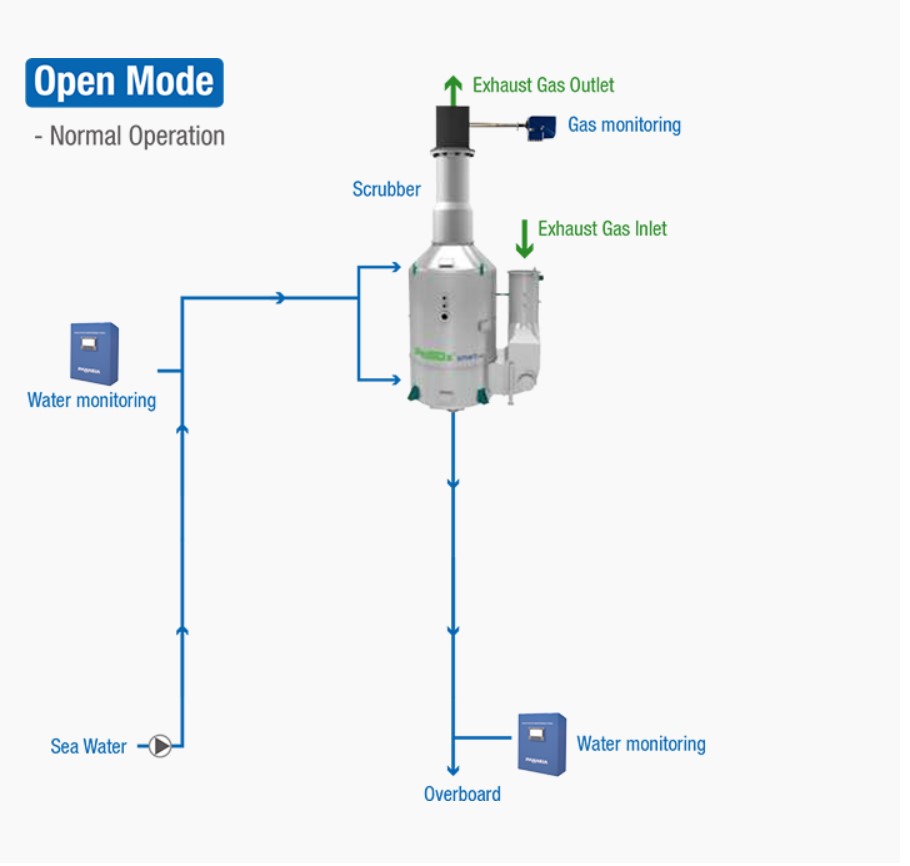

System Diagram

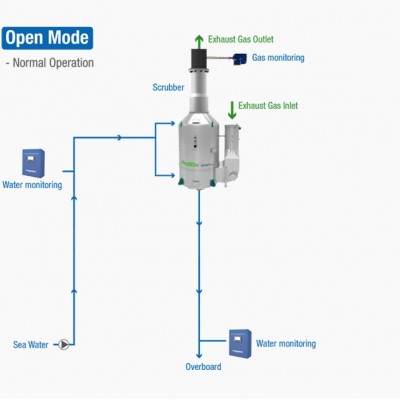

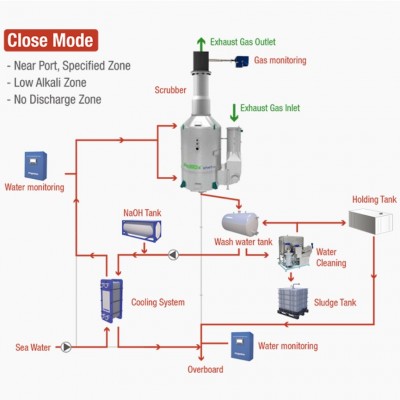

PANASIA PaSOx™ Exhaust Gas Cleaning System removes sulfur oxides in the marine environment. It is largely classified into the Open Mode, Close Mode, and Hybrid Mode. In Open Mode, seawater is used as wash water. In Close Mode, an alkaline solution is used as wash water. In Hybrid Mode, you can switch between Open Mode and Close Mode.

Open Mode System

In Open Mode, seawater is used as wash water.

This exhaust gas cleaning process utilizes the ability of seawater to remove sulfur dioxide naturally.

In the Open Mode System, seawater is supplied through seawater pipes.

The wash water from the scrubber is discharged to the sea.

The quality of such discharged water is monitored through the wash water monitoring system.

Exhaust gas discharged following treatment in the scrubber is monitored by a gas monitoring system in real time.

Close Mode System

In Close Mode, the system circulates wash water in the wash water tank.

Wash water is supplied to the scrubber at a constant temperature by the wash water pump through the cooler. The used wash water from the scrubber is collected back into the wash water tank and reused. The system monitors the pH level of wash water to automatically control and supply alkaline (NaOH) dosing to remove sulfur oxides.

During the reuse process, wash water is cleaned through the Wash Water Cleaning System.

The wash water cleaned through the Wash Water Cleaning Unit is either re-supplied to the wash water tank, discharged, or stored in the holding tank (discharge restricted area).

Sludge is generated in the water purification process of the wash water cleaning unit, and it is stored in the sludge tank. During the scrubber cleaning process, temperature rise of the wash water is managed by the cooler.

Certificates

Related Videos

https://www.youtube.com/watch?v=EINLInsWfMo&feature=youtu.be

https://www.youtube.com/watch?v=ZMDb47KYu84&feature=youtu.be

https://www.youtube.com/watch?v=oyuKN7LBK1M&feature=youtu.be

https://www.youtube.com/watch?v=JemMyZlDS8g&feature=youtu.be

https://www.youtube.com/watch?v=aDZLDxvnPXQ&feature=youtu.be

TRAINING

CENTERS

Scrubber systems are complex and require more crew training. This need is especially acute when performance is conditional on understanding the system’s limitations in variable water conditions such as salinity and turbidity.

For BPCO, crew training continues post-commissioning with a hands-on training center, as well as regular periodic on board training after system handover so that new crew members learn the system and existing crew members’ knowledge is refreshed.

This follow-on training helps to ensure continued safe and reliable operation of the Scrubber system for years to come.

Do you have a land-based Training Center?

BPCO 's Training Centers are open to Ship’s crew, Technical superintendents, Ship designers and consultancy offices. The Center includes classroom instruction on function, safety, troubleshooting and maintenance.

Do you offer on board Training?

The amount of time between getting the system fully operational and the vessel leaving the shipyard during the commissioning period can be very short. This limits the amount of time to provide hands-on training to the crew. Additionally, conditions do not mimic real-world experience of a scrubber operation. BPCO offers additional hands-on training, allowing for more time and a better experience with the engineers on board the vessel.

Do you issue certification?

Attendance Certification is issued upon successful completion of the Training Course.

PHOTO GALLERY

BROCHURES

Cookies Policy

Lorem ipsum, dolor sit amet consectetur adipisicing elit. Sed eveniet expedita cum autem, provident perferendis earum libero hic quasi excepturi modi voluptas eligendi ducimus quae nulla quis sapiente voluptate odio!

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Aut excepturi tenetur sunt quo, sequi reprehenderit assumenda facere unde, deserunt odio consequuntur non totam vel suscipit. Eum officia reprehenderit sit, inventore adipisci consequuntur commodi ducimus quisquam vel culpa dolorem error modi, aut distinctio odio excepturi non ut reiciendis obcaecati quis repellendus quia fuga. Corporis, sunt maiores eum recusandae distinctio exercitationem iure repellat autem saepe non sed reiciendis repellendus dolore doloremque ducimus ab alias modi itaque praesentium rerum ratione molestiae porro ullam. Quasi nostrum quas quia tempora recusandae, iusto voluptate commodi consequatur consequuntur! Id minus sequi nam enim omnis vitae aliquam ipsum ratione, neque sint vero ab repellendus quis nihil doloremque dolorem et reprehenderit, rem, repellat reiciendis earum ut doloribus totam? Corrupti omnis, sapiente, veniam eaque unde possimus quia in sit nihil qui totam asperiores amet suscipit soluta maiores. Reprehenderit repellendus corporis nihil amet, voluptate atque minima soluta, hic ea libero neque quod! Non suscipit iste odio error eius recusandae voluptates reiciendis dolorum qui libero nostrum eveniet, quod magnam amet laboriosam quaerat numquam minus explicabo delectus consequuntur at voluptatum quibusdam aspernatur doloremque! Aliquam, atque, recusandae veritatis, ab enim temporibus earum qui sunt cumque ipsa ducimus eum explicabo exercitationem non quidem velit vel.

Section 01

Lorem, ipsum dolor sit amet consectetur adipisicing elit. Consequuntur eos quasi facilis animi maiores ut cum repellendus, placeat ipsam voluptate quos quas nobis optio ipsum at soluta doloribus sapiente ullam nemo? Dolore nisi labore, quas reprehenderit aspernatur quo nobis doloremque, numquam quis ipsa quidem dignissimos beatae necessitatibus nulla dolor obcaecati, minus explicabo? Aliquid laboriosam rerum omnis molestiae eveniet odit officia distinctio adipisci ad dolorem explicabo, optio ducimus! Dolore, excepturi laudantium? Aut sed vero expedita optio qui nihil consequatur, adipisci, minus rem repudiandae earum, eius quis deserunt maiores! Reiciendis vel maiores modi id debitis harum fugit, odit tempora tenetur maxime mollitia.

Lorem ipsum dolor sit amet consectetur adipisicing elit. Suscipit mollitia recusandae sunt a quod explicabo et cum, perspiciatis iste, excepturi voluptatibus. Quo ex iure veritatis exercitationem saepe consequatur repudiandae minima!

Section 02

Lorem ipsum dolor sit amet consectetur adipisicing elit. Harum, labore praesentium veritatis incidunt in doloribus id minima rem laudantium optio dolor debitis accusamus veniam dicta quidem ipsum porro mollitia necessitatibus aliquid corrupti saepe dignissimos blanditiis deleniti! Quia, esse culpa. Totam repellat veniam pariatur repudiandae saepe quae officia corrupti quis quo nesciunt iusto at incidunt vero, praesentium neque illo vel id voluptas deserunt dicta dignissimos quod! Odit, eligendi error? Commodi repellendus optio aliquid, quidem rerum eaque, atque soluta possimus, doloribus amet nemo. Soluta molestias possimus itaque atque aut porro est ipsa nobis aliquam repellendus corporis totam quo mollitia quasi at, tempora animi, reiciendis dolore dolorum. Voluptate perferendis cumque vero voluptatibus eaque? Voluptas consequatur alias minima obcaecati amet voluptates provident rerum ducimus doloribus voluptatem, quis mollitia unde tempore perferendis nostrum, debitis magni deserunt explicabo odio veritatis tenetur. Est recusandae debitis expedita nam amet itaque facilis ut reiciendis fugit molestiae quis porro aperiam veniam, deleniti explicabo quod vitae, dolore officia sapiente numquam ratione, et voluptatibus. Quos cupiditate excepturi harum amet impedit doloribus dicta, fuga distinctio fugit exercitationem ipsam molestias maxime doloremque voluptatum nesciunt saepe eligendi? Dignissimos culpa aperiam eaque animi delectus quaerat repellendus perferendis officiis in reprehenderit asperiores eligendi hic aut, labore quas? Labore esse quae temporibus, obcaecati facilis blanditiis asperiores quod nisi rerum eaque velit tempora molestias sit modi voluptate. Eaque ab sed eligendi quas ex deserunt tempore molestias dolor quo culpa, at velit, iste, perspiciatis aperiam rerum recusandae nobis similique vitae! Provident necessitatibus deleniti repellendus neque maiores assumenda enim, incidunt earum ipsum quo corrupti placeat vitae libero alias architecto eveniet facere sint minus dolore id voluptates. Quis quasi voluptas id ipsum architecto provident ipsam eaque! Repudiandae, delectus? Accusamus aliquam, ullam vitae corrupti autem culpa distinctio eius aliquid tempore pariatur tempora officiis sed eos hic, dolor natus, nesciunt ducimus facere adipisci. Iure!